“

In today’s world, ensuring access to clean water is more critical than ever. Advanced technologies for water purification are at the forefront of this effort, offering innovative solutions to tackle water contamination and scarcity. These technologies are revolutionizing water treatment, from groundbreaking filtration systems to state-of-the-art disinfection techniques. Here are 20 fascinating facts about how these advanced technologies are making a difference in water purification and what the future holds for clean water solutions.1

1

”

Reverse osmosis (RO) uses a semi-permeable membrane with pores as small as 0.0001 microns, which allows it to filter out 99% of dissolved salts, heavy metals, bacteria, and viruses. 1

Ion Exchange (IX) in laboratory water purification involves passing water through ion-exchange beads that absorb impurity ions. These ions are replaced by hydrogen and hydroxyl ions. This process deionized and purifies the water.

RO technology is a key player in desalination plants, converting seawater into freshwater in regions facing water scarcity, such as the Middle East, providing millions with drinking water. 2

Microporous screen filters remove particles larger than the specified pore size, with 0.22-micron filters trapping bacteria. Positively charged membranes can capture endotoxins.3

RO is more energy-intensive than other filtration methods due to the high pressure required to force water through the membrane, especially in desalination, where seawater requires significant pressure.4

RO systems are widely available for home use, offering purified drinking water directly from the tap by removing contaminants like lead, chlorine, and fluoride that affect taste and safety.

RO units often include multiple pre-filters (sediment and carbon filters) that remove larger particles and chlorine, which can damage the delicate RO membrane, extending its lifespan.5

Researchers at Princeton University developed a Solar Absorber Gel that absorbs contaminated water at room temperature and releases it when heated. The gel's polydopamine layer converts solar energy into heat.6

Reverse osmosis produces wastewater, typically 3 to 4 gallons for every gallon of purified water, though newer models are designed to be more efficient, reducing waste to a 1:1 ratio. 7

Some industrial applications use dual-pass reverse osmosis systems, where water is filtered twice, significantly improving water purity for sensitive applications like pharmaceuticals. 8

RO filters out beneficial minerals like calcium and magnesium, which is why some systems include remineralization stages to add essential minerals back into the water for improved taste and health benefits. 9

The RO process has been a game-changer for countries like Israel, where desalination by reverse osmosis supplies over 50% of the country’s drinking water, helping to address water scarcity issues. 10

RO is used in the food and beverage industry to concentrate liquids (such as juice) and purify water, ensuring product consistency and safety for consumers. 11

RO systems are employed in wastewater treatment plants to remove harmful contaminants, including nitrates, phosphates, and heavy metals, before water is released back into the environment. 12

NASA developed Acoustic Nanotube filtration technique for use in space missions, providing astronauts with recycled water by purifying urine and wastewater onboard spacecraft.

RO membranes can last 2-5 years with proper maintenance, but their longevity depends on water quality and regular cleaning to prevent fouling from organic material and mineral deposits. 13

While energy-demanding, some RO plants are powered by renewable energy sources like solar or wind, especially in off-grid regions, making water purification more sustainable. 14

RO systems are essential for reducing salinity in agricultural water, especially in areas with saline irrigation water, which can harm crops, improving agricultural productivity and food security. 15

Photocatalytic water purification uses photocatalysts and ultraviolet rays to quickly remove toxic substances from water. This green technology is cost-effective and sustainable. 16

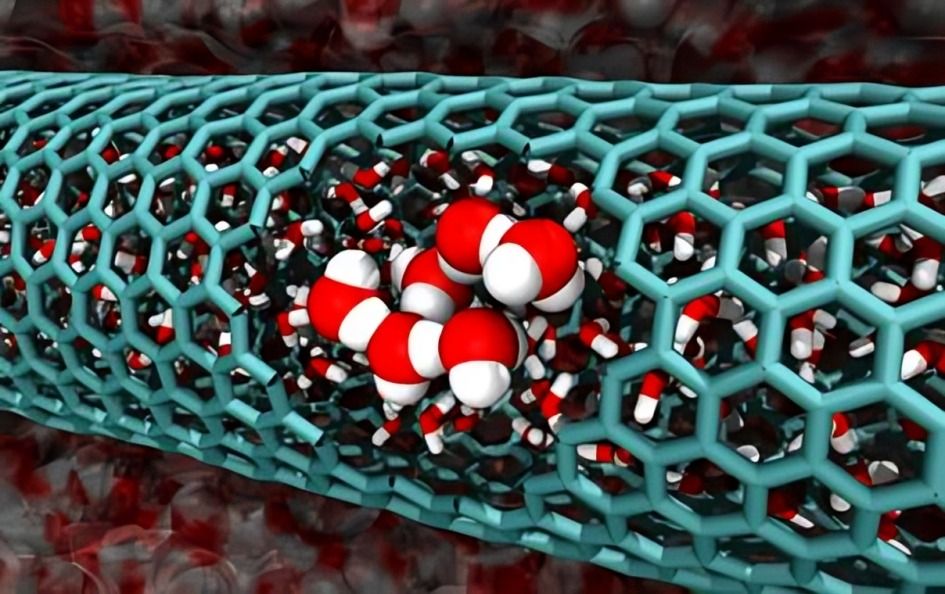

Nanotechnology applied materials at the atomic or molecular level for water purification. Nanotech-based processes are modular, efficient, and more cost-effective than traditional methods. 17